Shenzhen Sipotek Technology Co., Ltd. is a professional automatic visual inspection machine ,automated vision inspection system,industrial machine vision camera,automated optical inspection machine ,optical sorting machine manufacturer from china with low cost and high quality.

Optical sorting (sometimes called digital sorting) is the automated process of sorting solid products using cameras and/or lasers.Depending on the types of sensors used and the software-driven intelligence of the image processing system, optical sorters can recognize objects’ color, size, shape, structural properties and chemical composition.The sorter compares objects to user-defined accept/reject criteria to identify and remove defective products and foreign material (FM) from the production line, or to separate product of different grades or types of materials.

Optical sorting achieves non-destructive, 100 percent inspection in-line at full production volumes.Optical sorters are in widespread use in the food industry worldwide, with the highest adoption in processing harvested foods such as potatoes, fruits, vegetables and nuts where it achieves non-destructive, 100 percent inspection in-line at full production volumes. The technology is also used in pharmaceutical manufacturing and nutraceutical manufacturing, tobacco processing, waste recycling and other industries. Compared to manual sorting, which is subjective and inconsistent, optical sorting helps improve product quality, maximize throughput and increase yields while reducing labor costs.

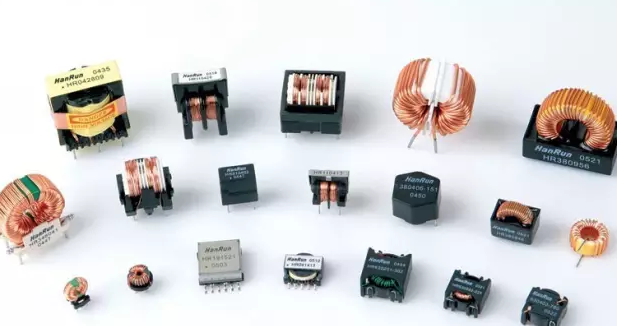

Today we will talking about creation of customized automatic visual inspection systems for magnetic inductor industries with automatic sorting machine function.

inductance element

Visual inspection systems have been immersed in the current market to the point of becoming not only a luxury, but a necessity in its competition. An industry that does not have a visual inspection system, has great losses and reduces its profits compared to its competitors, which can gradually lead to bankruptcy. However, manufacturers of visual inspection systems, have seen with a controversy, the number of industries that exist

It is clear that each specific industry has its primary verification needs: not all seek the same type of review, not all have the same product or need for verification, therefore most manufacturers of visual inspection systems have opted for work using their capacity to create customized systems according to each company and their possible needs

What variants can these custom inspection systems have?

Each one comes with a large number of features, to the point of being able to arm with a broad desire, exactly the system that suits your company.

First we can find the integrated systems to reduce the environmental impact. The space in the production plant is usually scarce, which can make the idea of adding additional equipment to the production line seem an insurmountable obstacle. However, with the placement of smart cameras, a visual inspection component can be integrated into existing production equipment, or work with an original equipment manufacturer (OEM) to develop a combined system that minimizes the footprint of any inspection equipment .

Following this is the different configurations of flexible cameras. They are smart cameras that are uniquely manufactured and offer fast processing times and support for high resolution options. A unique liquid lens option means that changes in focus can be executed without moving parts, making adjustments easy to make. Together with good product inspection software, it simplifies the change between product inspection profiles and allows you to easily export production data.

We also consider the implementation of software with a good PC-based inspection power. For more complex inspection solutions, different software support inspection applications that may require lighting and arrangement of single cameras. Connectivity with other production software allows the exchange of statistical data and remote access and control of the vision system.

Finally, Project management and support with OEMs is taken into account. The manufacturers of visual inspection systemsare aware that there is not always room for the placement of an independent system in the production line, and they are also aware that in some cases, it is illogical to place it since the components do not make sense to the time of separation of the production system. Therefore, manufacturers of visual inspection systems have come to the option of working together generating equipment each time they compete with each other and minimize poor and unreliable systems.

All these variants end up returning to the visual inspection system a much more pleasant option at the time of its placement within the different types of industries. The fact of being able to make customizable (many in addition to those already mentioned) allow to create a team totally focused on a specific task, maximizing the quality of production, saving matter and generating a better profit towards the company.

For more about visual inspection machine,you can pay a visit to sipotek at https://www.sipotek.net/machines/

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

Sipotek Visual Inspection Machine

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net

Website: https://www.sipotek.net

Myspace:https://myspace.com/sipotek

Instapaper:https://www.instapaper.com/p/sipotek2019

Hardwaremassive:https://hardwaremassive.com/sipotek

http://sipotek.inube.com/blog/8600653/best-visual-inspection-machine-manufacturer-in-china/

https://sites.google.com/site/visioninspectionsystem/

https://sites.google.com/site/visioninspectionsystem/

No comments:

Post a Comment