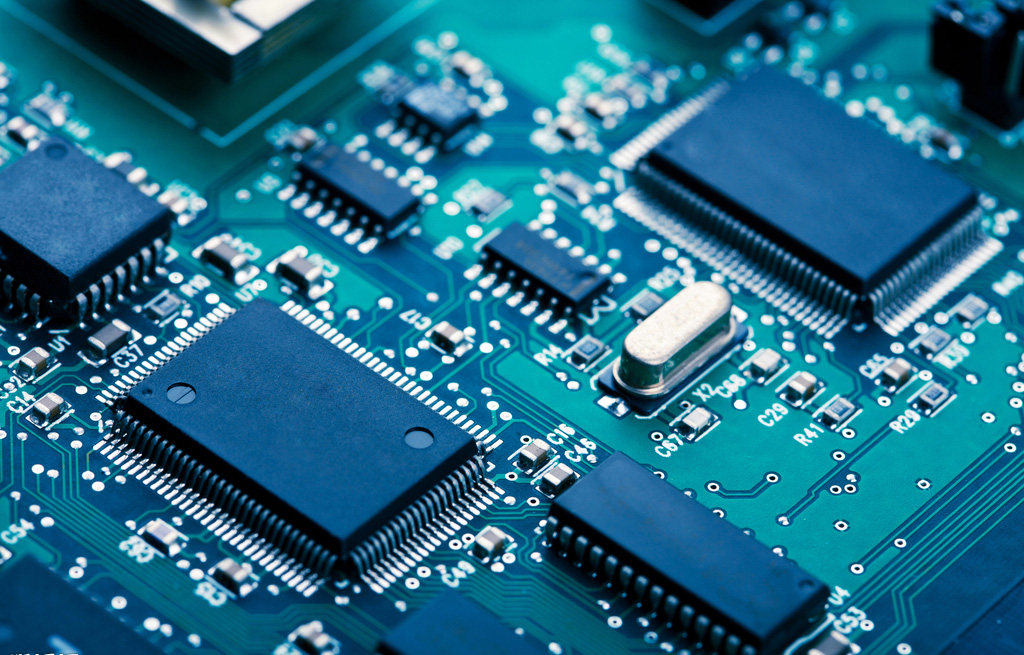

Sipotek CCD visual inspection machine application for exterior inspection, defect inspection, size inspection, scratch inspection, glitch inspection.

Sipotek CCD visual inspection machine use for electronic Components, Precision hardware, Stamping plastic, Silicone rubber, Medicine, food and more industries.

Among the different methods of non-invasive quality control, we find the most basic, although not least, the visual inspection machines.

From the first moment in which the machine is installed, the visual inspection is started as the first element of judgment to give the acceptance of an individual piece or of a system as a whole, prior to putting it into operation, or well as the first control to subsequently carry out the following conclusive tests, which will give the go-ahead for its operability.

Visual inspection machines allow the determination of the general integrity status of a part or component, including the detection of cracks, wear, corrosion, erosion or any physical damage to its surface. In the same way, it allows the detection of leaks of the components that retain pressure, and possible path of the leak that could affect the integrity or correct operability of the same and of other components.

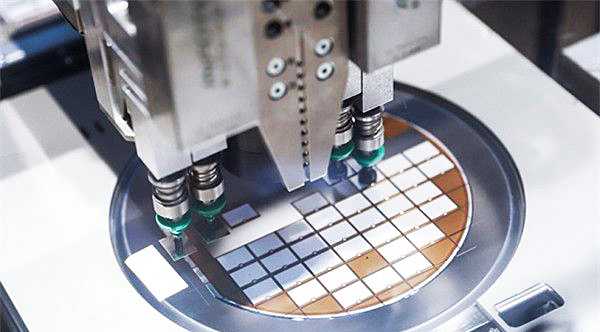

The inspection carried out by the machine is done at a short distance from the object, taking full advantage of the visual capacity. Magnifying lenses, microscopes, lamps, flashlights are used and, often, measuring instruments such as gauges, micrometers and gauges are also used to measure and classify the conditions found. All this is done by the machine The inspection carried out by the machine is done at a short distance from the object, taking full advantage of the visual capacity. Magnifying lenses, microscopes, lamps, flashlights are used and, often, measuring instruments such as gauges, micrometers and gauges are also used to measure and classify the conditions found. All this is done by the machine The designs and services of the CCD visual inspection machines must be adapted to the specific needs of each client. That is why these machines have so many uses and applications nowadays, since they allow different adaptations to the different needs.

Some applications are:

Measurement: Sub-pixel measurement tools, combined with the necessary optics and stable illumination, provide accuracy and repeatability to ensure manufacturing accuracy.

Verification: Verification is often combined with other jobs, such as measuring the dimension of the object or reading barcodes of products.

Recognition: Recognition is used in artificial vision to segment, classify or count elements that have certain characteristics in common.

Positioning: Positioning tools range from a simple edge locator, to the most sophisticated pattern recognition algorithms.

Detection of defects: The defects that can occur in the products are usually random, so the vision systems seek changes in the patterns.

Identifies materials that do not meet specifications, facilitates the correction of defects during the manufacturing process and reduces the need for subsequent non-destructive testing.

These machines are applied in a large number of companies from mechanical companies to companies such as laboratories and pharmaceutical clinics. Due to its large number of uses the company Sipotek has developed the best visual inspection machines to meet all the needs that customers may have regarding their visual inspection machines. Sipotek has made a wide range of visual inspection machines, which you can check in their web page

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net

Quora:https://sipotekchina.quora.com/

Blogger:https://automatedopticalinspectionmachine.blogspot.com/

Mix:https://mix.com/sipotekchina1

Blogger:https://automatedopticalinspectionmachine.blogspot.com/

Mix:https://mix.com/sipotekchina1

Website: https://www.sipotek.net